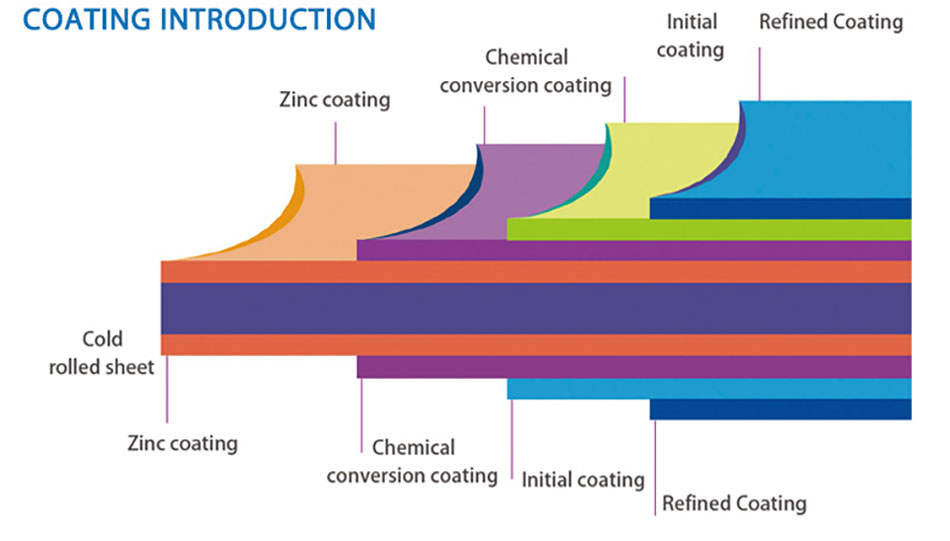

With GI and GL as the substrate, after surface pre-treatment, paint coating, baking and cooling, an organic protective film is formed on the steel substrate It has strong durability, corrosion resistance, decoration and formability, widely used in construction, household appliances, solar energy, transportation and other industries

| Standard | JIS G3322 CGLCC ASTM A755 CS-B | Surface coating color | RAL colors |

| Back side coatingcolor | Light grey ,white and so on | Package | export standard package or as request |

| Type of coating process | Front: double coated&double drying. Back: double coated&double drying, single-coated&double drying | ||

| Type of substrate | hot dipped galvanzied, galvalume, zinc alloy, cold rolled steel, aluminum | ||

| Thickness | 0.16-1.2mm | Width | 600-1250mm |

| Coil Weight | 3-9Tons | Inside Diameter | 508mm Or 610mm |

| Zinc Coating | Z50-Z275G | Painting | Top: 15 to 25 um (5 um + 12-20 um) back: 7 +/- 2 um |

| Coating introduction | Top paint: PVDF, HDP, SMP, PE, PU | ||

| Prime paint: Polyurethane, Epoxy, PE | |||

| Back paint: Epoxy, Modified polyester | |||

| Productivity | 150,000Tons/year | ||

| Production core strengths | |||

| Resistance to acid rain: | |||

| Coating protection mechanism: It is very easy to form acid rain in the high level of industrial emissions or pollutants environment. Acidic penetration is formed in the surface of pre-painted steel, and accelerates the corrosion, forming blistering, peeling and so on. | |||

| Resistance ultraviolet rays: | |||

| Coating protecting Mechanism: pre-painted sheet in ultraviolet or strong sunlight conditions, the coating will exhibit chalking degeneration, manifested as discoloration and loss of gloss, lose paint quickly. | |||

| Resistance to humid heat: | |||

| Coating protecting mechanism: in hot and humid environments, high osmotic pressure of water vapor accelerates penetration, forming the degeneration of painting film, then the corrosion of the substrate, with the phenomenon of bubbles and peeling. | |||

| Resistance to low temperature: | |||

| Coating protecting mechanisms: most of the paint can keep stable processing performance above 0 degree, but at alpine region, the temperature will be below 20-40 degree, normal paint will become brittle,bend cracking, or even lose paint, thus protection function is lost totally. | |||

Why Choose US?

Before- Sale service:

1. ISO Verified Outstanding Manufacturer

2. The third party inspection: SGS, BV, CE, COC, AI and other .

3. Flexible Payment : T/T, LC, O/A, CAD, DAP , KUNLUN Bank

4. Sufficient Stock

5. Quick Delivery Time, Long time price validity.

6. Tracking picture of transport : production, Loading and reinforcement loading Pictures

7. Rich experience Professioal Sale Team

After- Sale service:

1. Quality Guarantee after Receiving the Goods:

Offer money return or Ship new products for free if any problems happen

2. Technical Guidance for further Processing

3. VIP Service and Free Order after Accumulated Order Quantity